Navigate

The real world problem

Glaucoma is an eye disease affecting about 4% of the population over 40 years of age which can lead to blindness unless treated early. One of the symptoms of glaucoma is an increased intraocular pressure. It has long been recognized that, since intraocular pressure varies during the day, continuous monitoring of glaucoma patients is needed. The static measurements currently performed by ophthalmologists during office hours are not able to detect pressure peak variations.

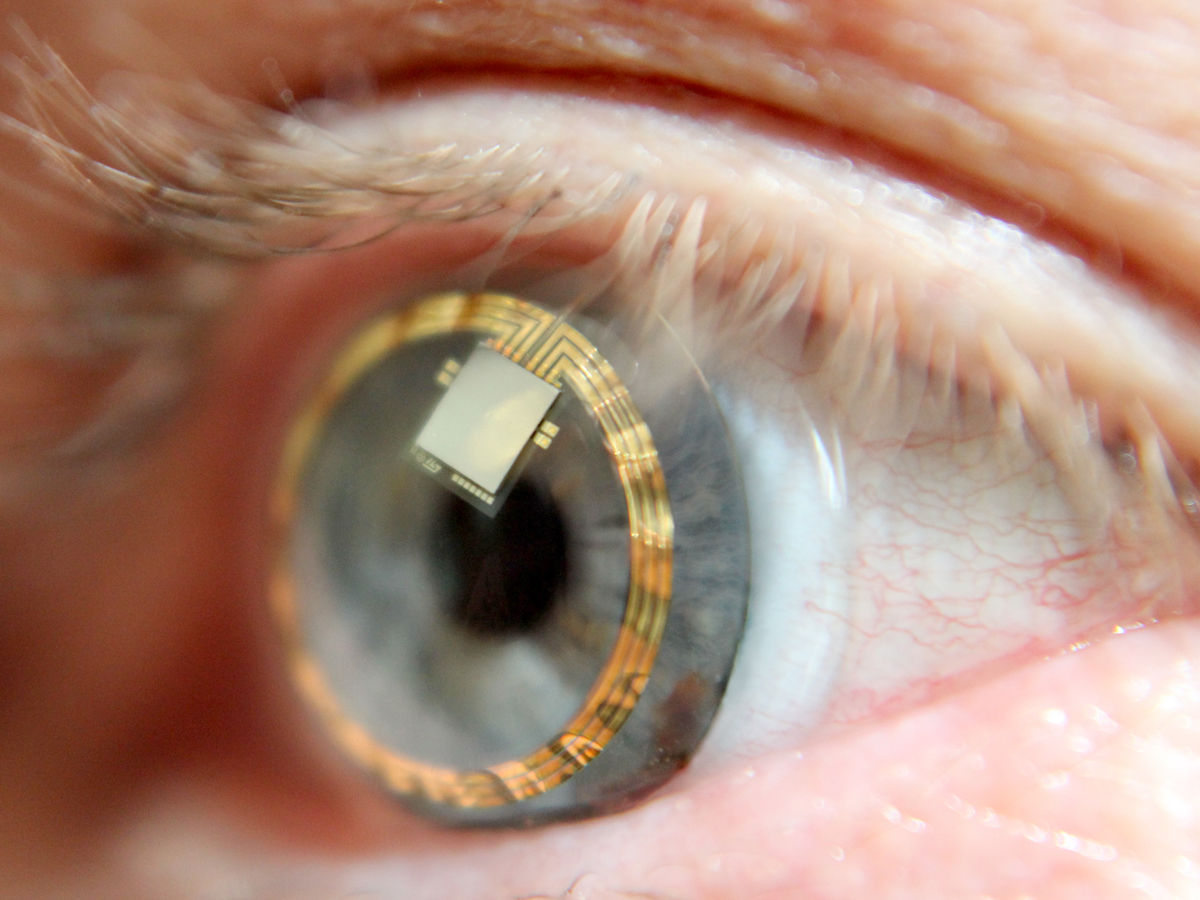

Sensimed AG, a Swiss company specialized in design, development and commercialization of integrated micro-systems for medical devices developed a soft hydrophilic single use contact lens called SENSIMED Triggerfish®. The passive and active strain gauges embedded in the silicone of the lens monitor fluctuations in intraocular pressure through variations in diameter of the eye.

Since there is no possibility to place a battery within the structure of the lens the system must power itself entirely from a localized magnetic field emitted by an RF Antenna worn around the eye and connected to a portable data recorder through a thin flexible Data Cable.

The patient wears the Sensimed Triggerfish® for up to 24 hours and undertakes normal activities including sleep periods. When the patient returns to his doctor, the data is transferred from the recorder to the practitioner's computer via Bluetooth technology for immediate analysis.

The solution

AnSem developed an ASIC for Sensimed to mount directly within the contact lens. The ASIC digitizes the MEMS sensor reading and transmits the measurements back to the recorder via the same RF link used to power the device using load modulation techniques.

By choosing ON Semiconductor's I3T50 0.35µm process, AnSem was able to incorporate power capture and conditioning, RF signaling, high linearity ADC and digital control functionality on a single die within the meager power budget and at low cost. Sensimed also benefits from the security of supply afforded by the automotive qualified process, which is so important to them in the medical electronics field.

Result for the customer

AnSem was able to meet Sensimed's requirements for a high sample rate and high ENOB digitization process while keeping within the power resources of the Triggerfish® coil antenna. AnSem manages the complete ASIC life cycle for Sensimed, including design, prototyping, industrialization and supply chain for volume production. The bumped die is attached directly onto copper traces within the lens during manufacture, connecting it to the antenna and MEMS array.

Key technical statistics

- 13.56 MHz loosely coupled inductive link for power and data

- Back-scattering communication via load modulation

- 17b sensor ADC on board with low noise sampling structure and temperature variation compensation

- Full CMOS implementation, highly efficient rectification avoids the need for Schottky diodes

- Wheatstone resistive bridge sensor reading, analog to digital conversion and data feedback through magnetic link.

- Sub 5 µV ADC

- Offset and slope correction technique embedded

- Supplied through magnetic link

- Data feedback through magnetic link

- Wide range of incoming wireless energy

Convinced by our success stories?

Let's get in touch!

- Your partner in analog, RF and mixed-signal ASIC solutions

- Custom mixed-signal IC design

- Turnkey ASIC supply for leading OEM companies

- Serving the industrial, medical and automotive markets

- Number 1 independent wireless IC design center in Europe

- Bringing innovation on chip

AnSem · Analog, RF and Mixed-signal ASICs

© 1998 – 2025 AnSem. All rights reserved.